NEWS

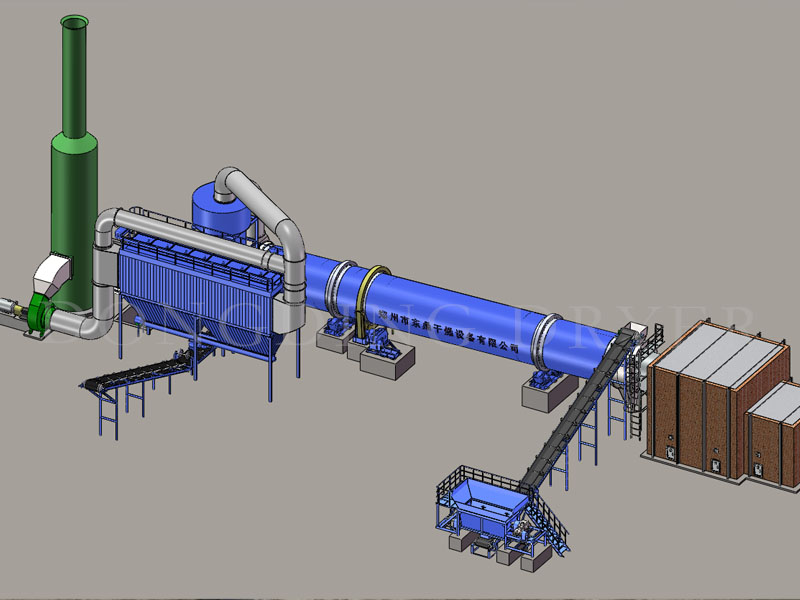

Rotary Drum Dryer VS Rotary Kiln

Writer: admin Time:2019-09-22 17:22 Browse:℃

Rotary drum dryer and rotary kiln has similar shape and working principle:

Each has a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its longitudinal axis. The process feedstock is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down toward the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal.

The differences of rotating drum dryer and rotary kiln are:

1.Different application:

A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include:

Cement

Lime

Refractories

Metakaolin

Titanium dioxide

Alumina

Vermiculite

Iron ore pellets

Kilns are also used for roasting a wide variety of sulfide ores prior to metal extraction.

Rotary drum dryer is applied to:

Coal drying

Wood chips drying

Sawdust drying

Fertilizer drying

Cow Dung Drying

2.Different lining constructions:

Rotary kiln has a refractory lining to insulate the steel shell from the high temperature s inside the kiln, and to protect it from the corrosive properties of the process material. It may consist of refractory bricks or cast refractory concrete.

Drum rotary dryer has the iron lining which is the same to the body shell and the lifting plate.

PRODUCTS

CONTACT US

Phone: +86-371-55091029

Tel / WhatsApp: +86 18538798892

Add: Zhengzhou Dongding Machinery Co., Ltd