THICKENING DEWATERING EQUIPMENT

High Frequency Dewatering Screen

- Product ID:THICKENING DEWATERING EQUIPMENT

- Phone: +86-371-55091029

- Tel: +86 18538798892

- Email: sale@zzddjt.com

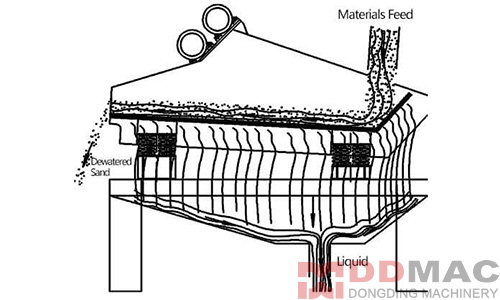

High Frequency Dewatering Screen Introduction

High frequency dewatering screen is the most suitable machine for sand and tailings dewatering process. They are designed as linear vibrating screen that widely applicated to dewatering, desliming, sculting, washing, degritting and screening. Dewatering screens as the most widely used dehydration product, which are mainly to produce a consistent dripless finished product and handle sand, gravel, aggregates, artificial sand, sea sand, clay, ores, tailings, coal, mining and other materials.

High Frequency Dewatering Screen Working Principle

High Frequency Dewatering Screen Advantages

1.Vibration damper more suitable for wet conditions and durable

2. Uses the embedded wear-resistant urethane mesh

3.High efficiency

4.Quality stable

High Frequency Dewatering ScreenTechnical Parameter

| Model | Power (kw) | No. | Capacity (t/h) | Feed size (mm) | Screen parameter | Weight (kg) | Dimension (mm) | ||

| Screen size(mm) | Screen area (m²) | Screen material | |||||||

| TS0918 | 1.1 | 2 | 10-30 | ≤10 | 900*1800 | 1.6 | PU | 600 | 1885*1290*1077 |

| TS0924 | 1.1 | 2 | 10-30 | ≤10 | 900*2400 | 2.2 | PU | 850 | 2483*1290*1215 |

| TS1224 | 2.2 | 2 | 30-60 | ≤10 | 1200*2400 | 2.88 | PU | 1100 | 2485*1590*1424 |

| TS1230 | 2.2 | 2 | 30-60 | ≤10 | 1200*2400 | 2.88 | PU | 1225 | 3084*1590*1439 |

| TS1236 | 3 | 2 | 30-60 | ≤10 | 1200*3600 | 4.32 | PU | 1468 | 3677*1590*1498 |

| TS1530 | 3 | 2 | 60-100 | ≤10 | 1500*3000 | 4.5 | PU | 1357 | 3083*1890*1433 |

| TS1536 | 3 | 2 | 60-100 | ≤10 | 1500*3600 | 5.4 | PU | 1750 | 3683*1890*1445 |

| TS1836 | 5.5 | 2 | 100-130 | ≤10 | 1800*3600 | 6.48 | PU | 3030 | 3717*2423*1927 |

| TS1842 | 5.5 | 2 | 100-130 | ≤10 | 1800*4200 | 7.56 | PU | 3434 | 4368*2421*2104 |

PRODUCTS

CONTACT US

Phone: +86-371-55091029

Tel / WhatsApp: +86 18538798892

Add: Zhengzhou Dongding Machinery Co., Ltd