GOLD CIP/CIL/CARBON CYANIDATION PLANT

Hard Rocks Gold Mine Flotation Cyanidation

- Product ID:GOLD CIP/CIL/CARBON CYANIDATION PLANT

- Phone: +86-371-55091029

- Tel: +86 18538798892

- Email: sale@zzddjt.com

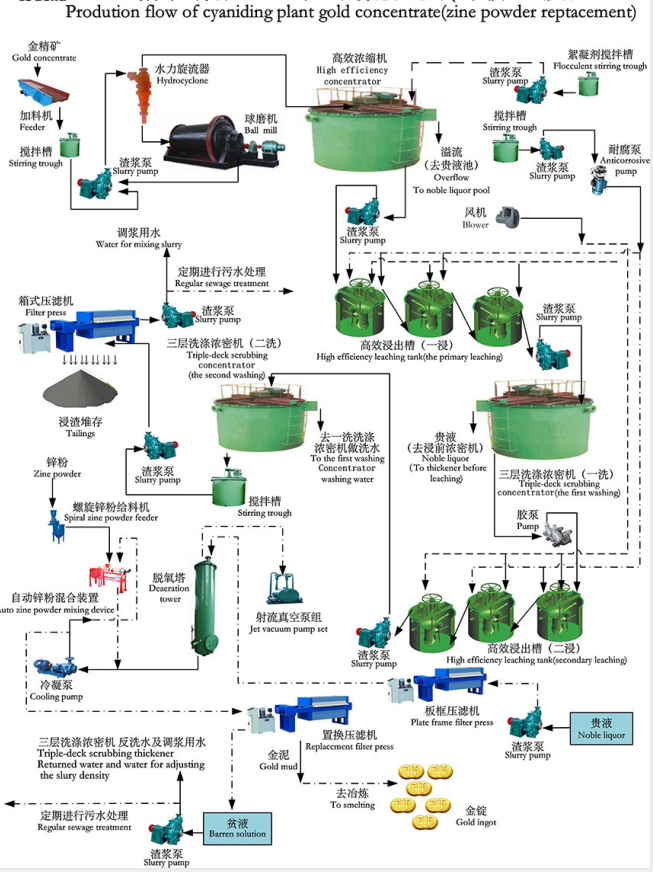

The floatation-ore concentrate cyanidation process is usually used for vulcanized primary ore and the ores with low silt content and high recovery rate that are easy to concentrate during floatation. .

Feature

After the floatation and concentration, the gold grade is improved, less material gets into cyanidation procedure. The consumption of cyanide is reduced, and as a result, the environmental pollution is minimized. In this way, construction investment and production cost is reduced and the goal of on-site gold concentration is achieved.

Floatation-ore concentrate cyanidation process is applicable for processing auriferous quartz type sulfide ore. Hence, the metal sulfide ore flotation concentrate with higher gold content cannot use cyanidation process before calcinations

The total recovery for the above ores that pass through the floatation-cyanidation process is about 95%. Additionally, acidization can be used to process the cyanide collected from tailings sewage. In this way, about 70% of cyanide in barren solution can be recycled. . Acidization principle: under acidic condition, the high-concentration cyanide (2100-2300 mg/L) in barren solution can release highly toxic HCN gas that can be absorbed in NOH to produce NaCN. . Acidization recycling cyanide presents significant business economic benefit and environment benefit

PRODUCTS

CONTACT US

Phone: +86-371-55091029

Tel / WhatsApp: +86 18538798892

Add: Zhengzhou Dongding Machinery Co., Ltd